Michael Matthews, Director of Customer Training and Education at Agiliti, joined Hank Balch and Justin Poulin from Beyond Clean to discuss all things instrument repair on an episode of Around the Table. In their conversation, they covered a range of topics which have a big impact on the outcomes in the OR and sterile processing departments, including:

- Best practices for reviewing the surgical instrument repair process

- Essential questions to ask your repair vendor

- Time-based vs. usage-based maintenance schedules

Below is a recap of the key topics covered in their conversation.

Topic #1: How to identify failure points and trends in your repair processes

Normal wear and tear of surgical instruments is unavoidable, but there may be overlooked gaps in your current processes that could be driving up unnecessary repairs. Here are two ways you can identify opportunities for improvements:

1. Look for visual cues on your surgical instruments:

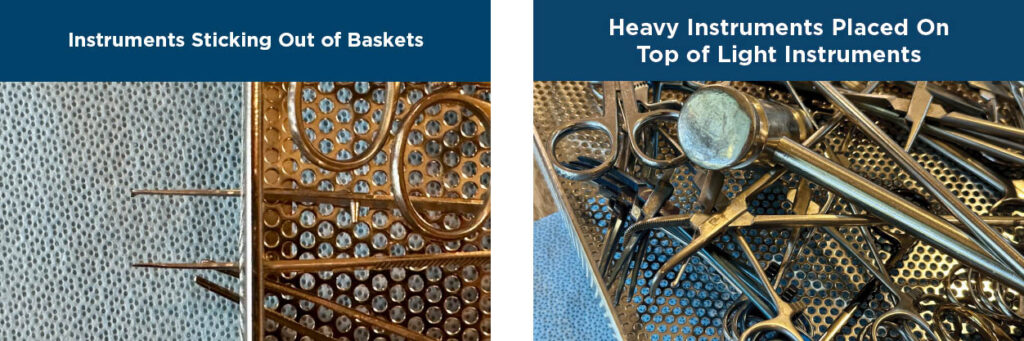

- What condition are your instruments in when they come back from the OR?

- Are instruments sticking out of the baskets?

- Are instruments being mishandled in the OR (ex. are heavy instruments placed on top of light instruments)?

- What’s the condition of your water*?

Technicians and managers should regularly keep an eye out for these visual cues to help address failure points and avoid unnecessary instrument damage (and costs). If you notice these visual cues, you should talk with your repair vendor to put a corrective action plan in place and initiate training related to instrument care and handling.

*Read more about water quality in our blog, “6 Surgical Instrument Cleaning Tips to Protect Patient Safety and Save Money”

2. Engage your repair vendor and utilize your surgical instrument repair reports:

- Have a conversation with your repair vendor about what’s included in your reports to help identify gaps, trends and potential failure points.

- Additionally, repair reports can tell you about the quality of your instruments – including what instruments are unrepairable (or not cost effective to fix) and if instruments are coming back with damage from the OR, reprocessing, etc.

- Monitor your repair reports – don’t throw them out! Your reports can help narrow down the process that is likely causing the damage. Using that information, discuss opportunities for improvement with your vendor.

Topic #2: Essential questions to ask your repair vendor

Not all repair vendors follow the same standards of quality when it comes to repairing surgical instruments. In the panel, Mike, Justin and Hank identify three important questions to ask your repair vendor.

1. Are you ISO 13485:2016 certified?

Safety and quality are non-negotiables when it comes to medical devices and ISO 13485:2016 sets the quality standard – which includes surgical instruments. It’s important to check your repair vendor is ISO 13485:2016 certified and follows rigorous quality management practices across their services, because third-party service providers do not require certification. Surgical instruments are used in many surgeries, so make sure you understand the background of your vendors to ensure their values align with your own quality expectations.

2. What type of training programs do you have for your repair technicians?

There is no set standard for the type and amount of training a repair technician receives. While technicians should be participating in regular continuing education opportunities, that’s not always the case. Ask your vendor what type of training their new and tenured technicians receive – along with their background and prior experiences – so you can better understand your repair vendor’s qualifications and training requirements. It’s also important that vendors have a training program for new repair technicians that includes an apprenticeship under a tenured technician who mentors them before they enter the field.

3. What data do you provide in your repair reports about what repairs are being performed?

Vendor transparency is vital to understanding both the strengths and weak points of your current processes. The repair reports from your repair vendor should include information about completed repairs, photos of documented damage and recommendations.

When a repair report is thorough and includes this level of detail, it can give you insights into your process and help you make the best decisions moving forward. The frequency of those reports can also be important in helping to get ahead of negative trends quickly – as well as identify future improvement opportunities.

Topic #3: Time-based vs. usage-based maintenance schedules

When it comes to surgical instrument maintenance, facilities can follow two types of schedules:

- Time-based maintenance schedule

Most hospitals use a time-based maintenance schedule, which means every six months or so, instruments get sent out for repair on a rotation. A schedule can make sure you aren’t forgetting any instruments, but it can also include instruments that don’t need to be repaired as often.

For example, an orthopedic mallet doesn’t need the same frequency of repair as a micro instrument. You can adjust time-based schedules to account for this, but this type of schedule can’t provide you with information about how many times that instrument has been used in the OR and reprocessed, which is what leads to damage in the first place.

- Usage-based maintenance schedule

A usage-based maintenance schedule is more efficient than time-based because it makes sure your instruments are only being repaired when they need to be – and no more. For a usage-based maintenance schedule to work, there must be a digital tracking system in place that tells you how many times an instrument has been used, gone through reprocessing and when it needs to be sent out for repair.

Without a usage-based system in place that tracks every time an instrument goes to a different touch point – like prep-and-pack or loading a set into a case cart – it can be difficult to know when the instrument has reached its use capacity and needs to be sent out for repair.

If you are unable to implement a usage-based maintenance schedule, you can manually keep track of what is being repaired. Your end-of-day reports, repair reports and quarterly business review can help you do this. If half of your instruments are coming back from the OR damaged, that’s a sign to increase the frequency of repairs.

Your repair reports can also provide some indication that your instruments may have preventable damage, which could mean that you have a gap in instrument handling skills and need more education. Monitoring how much is being repaired can help you fine tune your frequency of repair. It’s not perfect or as accurate as usage-based, but it’s a start.

Interested in learning more?

Dive deeper into these topics and listen to the full roundtable discussion here. To access continuing education and pre-certification resources through our Agiliti U platform for sterile processing professionals, visit https://www.agilitihealth.com/clinical-support/education/ or contact us to set up a discovery call.