Are the increased costs and risk across a healthcare organization, including patients and staff, worth a cent saved on a line item basis? The answer should always be no – but that’s not always the case. Part 4 of a 4-part series exploring the gaps surrounding medical equipment quality.

Evaluating Hospital Vendor Quality

The growing complexity in modern healthcare delivery presents new and expanding quality and safety challenges. “The difference is in the details” has never been truer, as healthcare organizations face the daunting challenge of managing medical equipment across a multi-faceted healthcare delivery environment. In the first three articles of this series (Here, Here, and Here), we highlighted how subtle and hidden quality variances in things like medical device management and medical laser operation can impact an organization’s quality engine. These variances can enhance or inhibit everything from operational efficiency, revenue, and the bottom line, to clinical outcomes and patient safety and satisfaction. In this final article, we will dive into why vendor quality matters and provide simple guidelines for evaluating and selecting high-quality service partners.

The Ugly Truth: Not All Hospital Service Providers Follow the Same Standards

Healthcare organizations are increasingly turning to vendors and service partners for medical equipment rental and service. However, what many healthcare organizations don’t know is that these third-party service organizations are not governed or regulated by the FDA like medical device manufacturers or healthcare providers — and thus are not mandated to have full quality management systems in place. So while most service providers take quality and patient safety seriously, not all go to the same lengths. The pace of change in healthcare continues to accelerate: technologies advance, regulations adapt, best practices evolve, and new patient safety risks emerge. In this dynamic environment, staying at the leading edge of patient safety practices requires a strong organizational commitment to quality.

Cutting Corners Up Front Equals Passing the Risk to Your Patients

Why would a vendor or service partner choose not to hold themselves to the highest quality standards? One answer is cost. Achieving independent certification, meeting or exceeding ANSI standards, and implementing a quality management system requires more intensive staff training, and more time and resource intensive risk-based protocols. The decision to cut corners on quality allows vendors and service partners to “pass the savings along to you” in the form of a lower line-item cost. However, by cutting corners in their internal operations and standards, they’re also passing along additional risks to you, your staff and your patients. Ask yourself, are the increased costs and risk across the organization worth a cent saved on a line item basis? Not when the impact is so great.

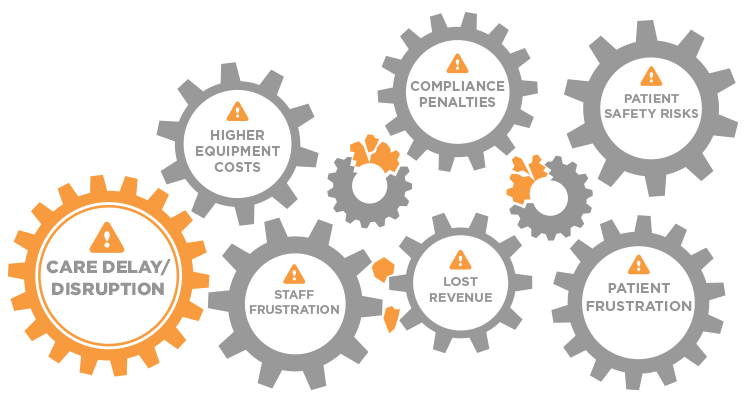

The Broad Impacts of Quality Gaps in Medical Device Rental and Service:

- Care Delay/Disruption: Device malfunction/servicing issues can delay care and disrupt clinical workflows

- Patient Frustration: Device malfunction and/or care delays damage patient experience

- Staff Frustration: Equipment issues frustrate clinical staff and contribute to burnout/turnover

- Higher Equipment Costs: Additional device repair and replacement costs

- Compliance Penalties: If a third party provides a non-compliant device or service, it is the healthcare provider that bears responsibility

- Patient Safety Risks: Device malfunction/failure can directly lead to adverse outcomes

- Lost Revenue: Care delays decrease patient throughput; lower patient satisfaction (and lower HCAHPS scores) can impact reimbursement rates and lead to patient volume leakage

The question becomes, how do I evaluate the quality of different third-party vendors? Now, let’s look at a few simple recommendations healthcare organizations can take when evaluating and selecting high-quality service partners.

What to Look for in a Hospital Medical Equipment Rental Provider

Smart rental practices play an important role within a healthcare facility’s goal to optimize inventory and reduce overall costs. But as we have demonstrated throughout this series, it is imperative to take steps to ensure your hospital medical equipment rental partner aligns with your quality goals. Equally important is ensuring that the rental equipment does not introduce risk to your facility. When evaluating vendor quality, start here:

Are Your Vendors ISO 13485:2016 Certified and Compliant?

The first and most critical question to ask a medical device rental or biomedical services vendor is, “Do you meet the ISO 13485:2016 standard?” The bottom line is that many vendors claim to be “ISO certified.” However, few self-adhere to this higher, healthcare-specific ISO standard. A standard which focuses on identifying and addressing the specific patient safety risks in a healthcare environment. Here are some questions you can ask to help identify any pitfalls your medical equipment vendors may have:

- Do they provide complete transparency – data and analytics – around the service history of rental devices?

- Do they follow OEM instructions and preventive maintenance schedules?

- Are all service technicians fully certified on the latest standards?

What to Look for in a Surgical Laser Partner

The updated ANSI safety standards (Z136.3) require healthcare organizations to make significant changes in their laser safety programs. This includes that laser operators have no competing responsibilities and maintain current certification on both the specific medical laser model and the particular procedure. As organizations consider these complexities and the ongoing costs of managing the needed certifications, most are looking to partner with a third-party provider of laser operation services. Here are a few simple tips to help you evaluate and select a trusted surgical laser service partner:

- Do they have their own medical laser safety officers (MLSOs) providing oversight of their laser operation service program?

- What is their process for maintaining technician certifications?

- Do they provide you with comprehensive, case-by-case laser logs and documentation for required ANSI reporting? Is this documentation and reporting easily accessible (e.g., online)?

- Will they provide the necessary training for your facility staff that works around medical lasers?

- Do they offer technician-only services that allow you to utilize your owned surgical lasers for procedures?

The Key Takeaway: Leading Vendors Recognize Higher Quality = Better Value

While adherence to higher quality and patient safety standards may not be required for vendors and service providers, forward-thinking vendors recognize the direct connection between quality and value. By self-enforcing the ISO 13485:2016 quality standard, or ensuring the latest laser operator safety certifications, independent service organizations that focus on doing the right thing recognize that they‘re giving healthcare organizations critical fuel for the quality engine. Likewise, savvy healthcare organizations are seeking out expert partners that self-adhere to the highest quality and patient safety standards. They’re asking tough questions to uncover small but important factors that impact clinical and business outcomes. By ensuring the quality of every input to their quality engine, healthcare organizations are supporting better patient experience, improving clinical outcomes, enhancing operational efficiency, and driving profitability and growth.

Read the Full Report Today

Want to learn more? You can download the full report today — from the nuances in ISO standards and how they impact patient safety, to tips for how to choose vendors that best support the delivery of quality clinical outcomes and exceptional patient experiences.

Visit our Resource Center to discover more, or return to the blog menu.